This Friday, after much anticipation and planning that went nowhere, I finally made a workshop. Joining me was Alex, my dear friend and flat-mate, and Sandy and Ryan who are students from the prep school. We convened at our apartment, and learnt together how to make leather from bacteria using kombucha cultures.

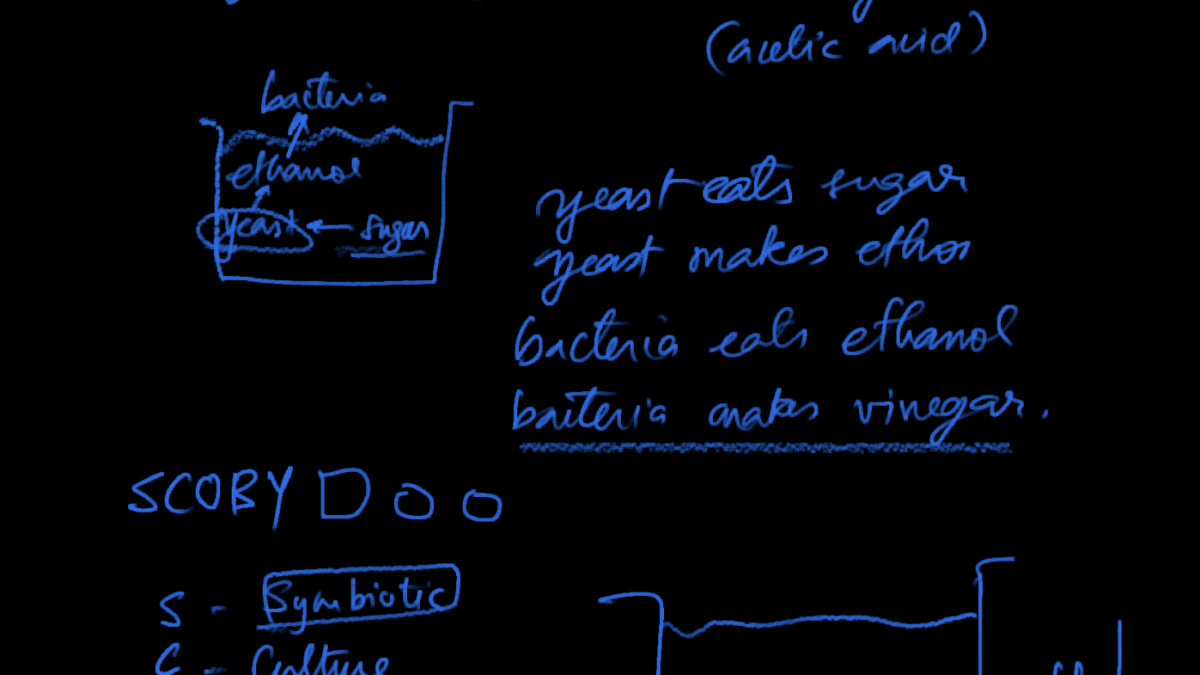

First, we went through the basics of brewing kombucha especially when one wants to extract bacterial cellulose from it. I showed the basic biology behind the method, and how the bacteria cleverly protects itself from the acid in the solution by creating the cellulose around it. It is this layer of cellulose that grows over time to create the Scoby – Symbiotic Culture of Bacteria and Yeast which is what we use to make the vegan leather.

We started by boiling some water to remove all possible contamination, and then dissolved 60g of sugar per liter of water. Then, we steeped 3 tea bags per 6L of water for 15 minutes, while allowing it to cool down to room temperature. Alex found a clever way to make it happen fast by submerging the hot vessel in cold water.

We then poured the cooled tea into plastic boxes after which I placed the Scoby in each of the boxes. After, we covered the boxes with paper towels to prevent any contamination, yet allow fresh air circulation to allow the bacteria the oxygen it needs to grow.

Then we began the perilous and arduous journey to take the boxes to the atelier where we will build the incubator place the boxes in, and to give the bacteria to grow in a nice and cozy environment. It was not easy, but we did it.

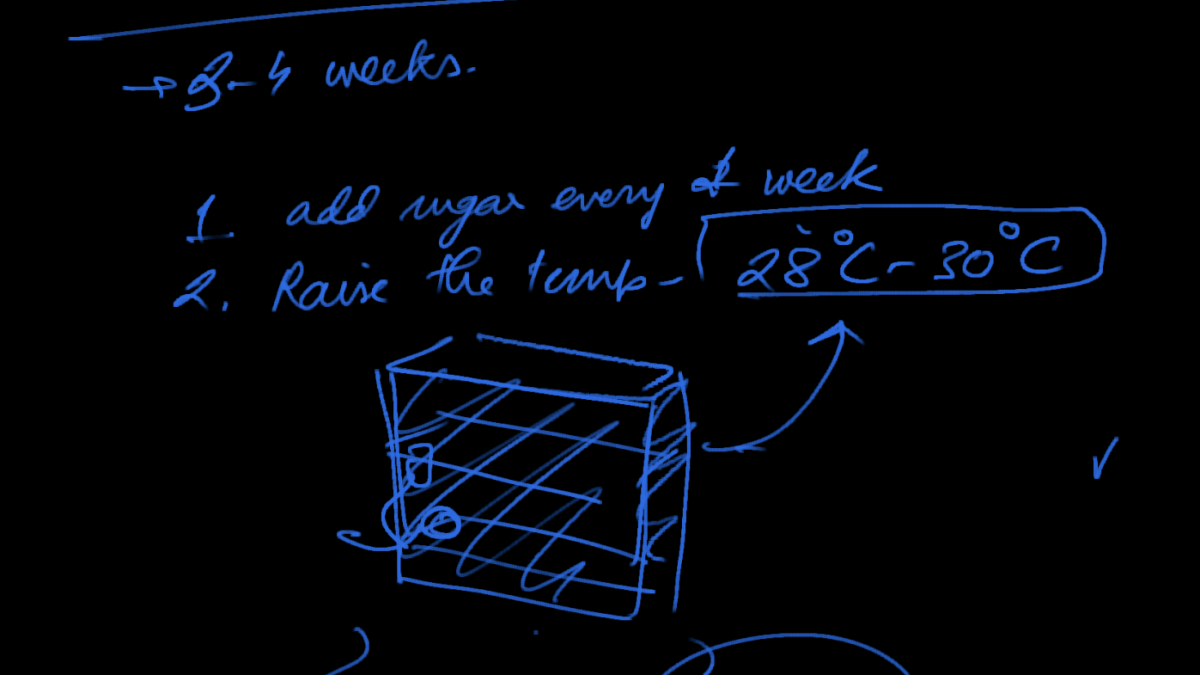

We then converted a rack into an incubator by covering with tarp on all sides, and then placing a heater and thermometer on it. This should keep the cultures at an even 28°C. This is necessary to allow the SCOBY to grow to an acceptable thickness in about 3 weeks. Once done, we will extract the SCOBY from the top, process it to remove the acid, and buff it with a mixture of oil and wax to give a supple texture like leather, and more importantly, to prevent any moisture to be absorbed by the cellulose.

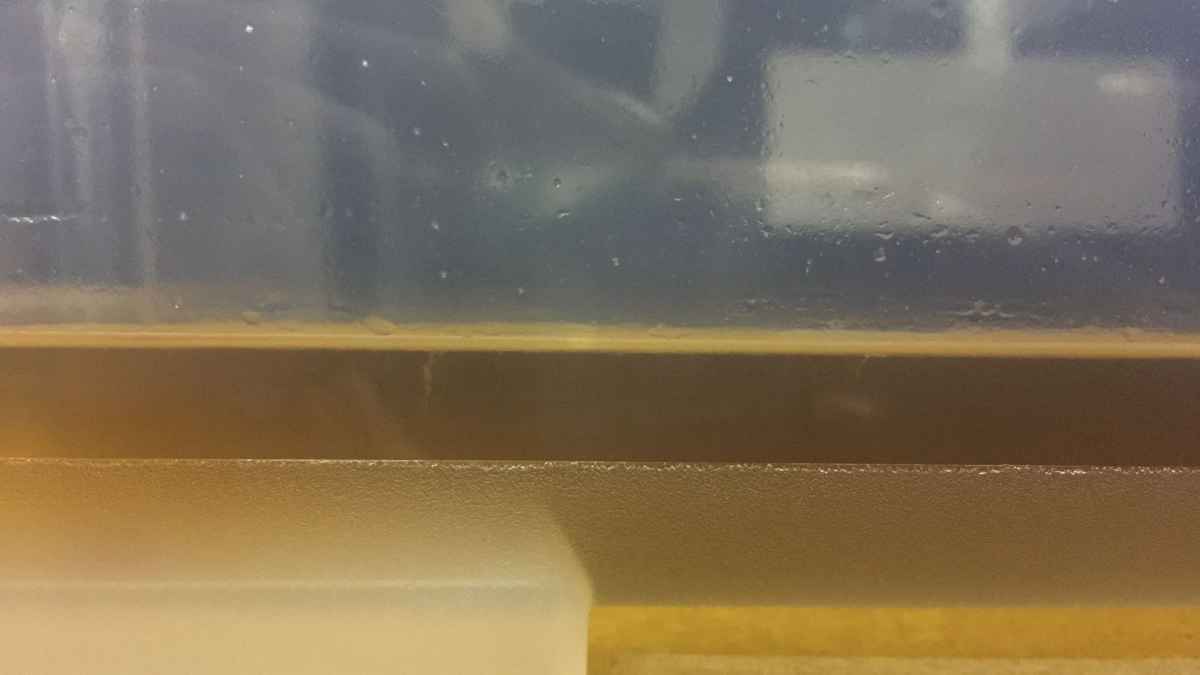

Unsurprisingly, even within 24 hours of incubation, there was already a thin layer of bacteria actively forming the bacterial cellulose layer. Soon enough, the layer would be thick enough, and we will add more sugar and water to the solution to provide more food to the yeast.

If all goes well, which we’ll make sure of by rigorously monitoring the growth, we’ll soon have a thick healthy Scoby to do all sorts of experiments. Soon, we’ll be making more of such experiments.

Stay tuned for more updates!

Se permettre l’écriture chez les designeur·euse·s, artistes et/ou chercheur·euse·s (☀✬❀)Revue Azimuts - Design Art Recherche

Votre navigateur est obsolète, l’affichage des contenus n’est pas garanti.

Veuillez effectuer une mise à jour.